How Agni Steels Achieved India’s Lowest Emission Intensity in Green Steel Certification with sentra.world

Table of Contents

Company Overview

Agni Steels Private Limited took up the decision to get Green Steel Certified at a time when sustainability in construction and infrastructure space is rapidly evolving. Through India’s Green Steel Certification framework which is administered by National Institute of Secondary Steel Technology (NISST), Agni Steel took a strategic and important decision to validate its sustainability practices and performance amidst growing emphasis on low carbon materials.

About Agni Steels:

- Product Focus: Manufacturing high quality TMT bars infrastructure and construction applications

- Operations: Integrated steel manufacturing facility based in Tamil Nadu, serving regional and national markets

- Production: 164490 MTPA, strong focus on process efficiency and quality standards

The objective behind this strategic move was clear – measure carbon emissions, achieve compliance under the nationally acclaimed policy and obtain official certification that could be leveraged across markets and to have a point of differentiation among competitors.

Why Agni Steels Decided to pursue Green Steel Certification?

As the need for low-carbon building materials grows throughout India, Agni Steels pursued Green Steel Certification to strengthen its market position. The company rather than depending solely on internal claims saw the need to publicly certify its emissions performance through a recognized national framework, as sustainability is increasingly affecting procurement decisions by infrastructure developers, institutions, and large buyers.

Agni Steels had already made investments in effective operations and ethical production methods, but Green Steel certification by NISST made it possible to convert these efforts into validated carbon intensity data at the product level. Agni Steels strengthened its leadership in India’s secondary steel industry and the nation’s expanding green steel ecosystem by proactively implementing Green Steel Certification.

The Challenge

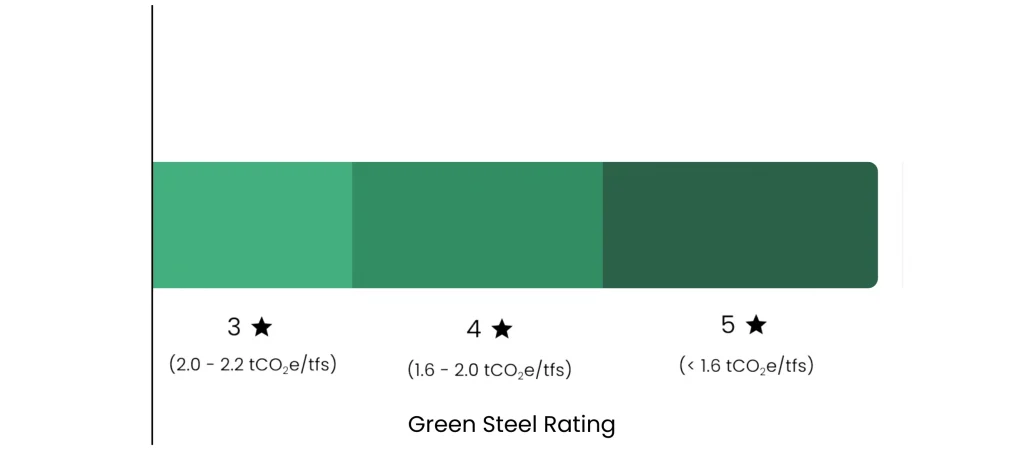

According to Green Steel Certification guidelines, given by NISST, steel products must demonstrate an emission intensity below 2.2 tCO2e per tonne of finished steel to qualify as green steel. The graph below illustrates how the star rating is provided for finished steel whose emission intensity is lower than the threshold value.

For a detailed overview of how green steel certifications are classified, refer here.

Calculations and processes the certification requires:

- Calculations of Scope 1 and Scope 2 emissions with limited Scope 3, upto finished steel production.

- Product level emission intensities

- Measurement, reporting and verification (MRV) that is conducted by BEE empaneled verifiers

- Third party verification by an accredited verification agency (ACVA) appointed by NISST

- Submission of documentation to NISST for final approval

Agni Steels has made operational improvements in their manufacturing processes over time, green steel certification required emissions data to be consolidated, calculated and presented in a consistent format aligned with NISST methodology and requirements. This created the need for a unified solution where carbon measurement, verification and reporting accuracy is the focus, and this is where sentra.world came in to make their process efficient and easy.

The sentra.world Solution

To get a more efficient process through their roadmap to Green Steel Certification, Agni Steels partnered with sentra.world, #1 Industrial Sustainability Platform, digitizing and streamlining their process end-to-end.

- Product Level Carbon Accounting

Using the product sentra.calculus , sentra.world helped Agni Steels in calculating precise product level carbon emissions for its TMT bars. Their fuel consumption, use of electricity and production data were captured and converted into emission metrics aligned with the Green Steel Taxonomy framework from NISST.

The digital platform ensures transparency in allocating emissions per tonne of finished steel which resulted in emission intensity of 0.4529 tCO₂e/tfs for Agni Steels – one of the lowest carbon emissions in India, which is significantly lower than eligibility threshold of 2.2 i.e. 5X better than the best!

- Audit Ready MRV and Support in Verification

For the complete MRV process, sentra.world supported Agni Steels with end-to-end process, including:

- Registration with NISST

- Data collection and calculation

- Supporting documents that meet audit-ready standards

- Coordinating efforts with an accredited third-party verifier (ACVA)

- Addressing verification inquiries and conducting robust data verifications

The workflows for all the documentation were easily traceable on the digital platform which simplified verification and reduced time, allowing the audit to be completed efficiently and smoothly without less back and forth between parties.

- Submission of Certificate and Approval

After the verification is successfully done by independent third-party auditors (ACVA) appointed by NISST, sentra.world assists in compiling and submitting the final dossier to NISST for approval.

The Outcome: Green Steel Certification

After the successful approval by NISST, Agni Steels was awarded a Green Steel Certificate for their TMT bar production for FY 2024-25 with production of 164,490 tonnes of steel output, with the following results:

- Emission Intensity:4529 tCO₂e/tfs

- Greenness Score:41%

- Star Rating: 5 Star Green Steel

- Validity: 31st March 2026

The certificate given by NISST is digitally verifiable and recognizes Agni Steels as India’s lowest carbon steel producer under Green Steel Taxonomy framework, till date.

Business Impact

Other than just achieving the Green Steel Certification, it delivered tangible benefits and business-oriented benefits for Agni Steels:

- Brand Credibility: An official validation for their sustainability practices from a government backed institution

- Market Differentiation: Strengthening of position with buyers and projects which are focused on sustainability

- Market Ready: A signal of alignment with emerging domestic and global regulations

- Future Preparedness: A carbon baseline that supports ongoing and future decarbonisation and compliance

Conclusion

Agni Steels’ certification journey demonstrates how accurate carbon accounting, structured MRV, and digital compliance tools are becoming essential for steel manufacturers in India. With sentra.world’s integrated digital platform and expert advisory support, Green Steel Certification was transformed from a complex regulatory exercise into a strategic business advantage against competitors.

India is accelerating towards low carbon transition and net zero by 2070, and sentra.world continues to enable industrial producers to move from carbon intensive to carbon zero future by helping in measuring, mitigating and monetising their CO2 emissions.

Are you interested in getting your green steel certification? Get in Touch Now!