What is CBAM?

Reducing carbon emissions is now a top priority for governments, industries, and international organizations, as outlined in the 2015 Paris Agreement. One proposed solution to this urgent problem is the implementation of a Carbon Border Adjustment Mechanism (CBAM) regulation. This mechanism is especially relevant for energy-intensive sectors like iron and steel, which are known to be significant contributors to global carbon emissions. European Union has long been taxing its industries for their carbon emissions under the EU ETS scheme, incentivizing them to adopt greener manufacturing processes.

CBAM Objective

EU ETS, however, led to an unintended consequence of carbon leakage with industries shifting carbon-intensive manufacturing parts of the supply chain to locations outside of the EU. CBAM is being introduced to address this problem and maintain the same treatment for goods produced in the EU and imported to the EU from other countries.

CBAM was introduced to address these objectives:

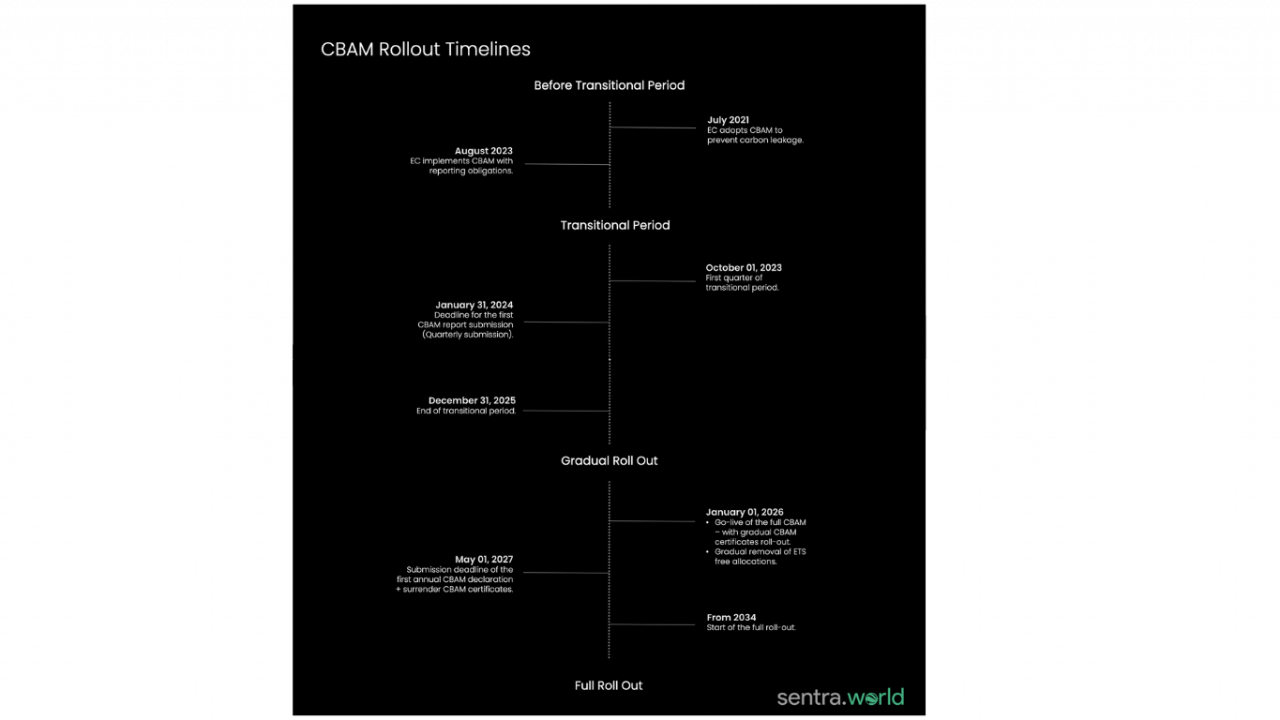

Timeline

The CBAM regulation will be implemented in two broad phases starting from the transitional period which will continue until 31-December 2025 leading to the gradual rollout which will continue till 2034.

CBAM: Threat or Opportunity for Indian Ferro Alloy Exporters

Indian ferro alloy manufacturers can master CBAM (Carbon Border Adjustment Mechanism) reporting by focusing on several operational and compliance-oriented steps. Here’s a brief overview of some of the key steps that can be taken by Ferro Alloy manufacturers to embrace sustainable change effectively and turn CBAM into a strategic advantage:

- Understanding the scope

It is of paramount importance that before beginning any reporting/measurement exercise, Ferro Alloy producers develop a good understanding of CBAM and its impact on their business. Some of the key questions that must be answered are:- Are my products covered under CBAM?

(Currently, only 3 ferro alloys: Ferro Chrome, Ferro Nickel, and Ferro Manganese are covered in CBAM) - How much of my business will be impacted?

- How will CBAM impact my cost structure?

CBAM’s implications will have a ripple effect across the supply chain resulting in cost pressures in certain markets

- Are my products covered under CBAM?

- Accurate Measurement

The adage “What gets measured gets improved” summarizes perfectly the need for Indian Ferro Alloy producers (particularly exporters to the EU) to set up robust GHG emissions calculation processes not just for quarterly reporting but for continuous tracking & improvement.- Set up robust data collection: Manufacturers must establish systems for gathering accurate emissions data at both the process and product levels.

- Calculate emissions based on EU CBAM methodologies: Ensure that emissions accounting is done per the EU standards and methodologies. They may differ from domestic Indian standards, so a review of the reporting frameworks is essential to eliminate any discrepancies

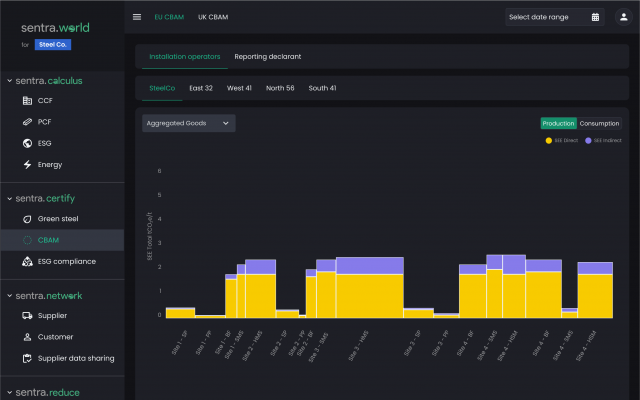

- Deploy carbon accounting software: Using digital tools like sentra.world for tracking, calculating, and reporting emissions will streamline compliance and turbocharge the company’s efforts to decarbonize their operations

- Engage supply chain partners: EU CBAM requires producers to measure & report their embedded (scope 3) emissions as well. While the body has published default values for commonly used raw materials, usage of the same is not permitted in case the share of such emissions exceeds 20% of the overall emissions.

- Establish verification procedures

CBAM reporting requires the validation of emissions data by independent verifiers accredited by the EU. Indian manufacturers must partner with credible third-party auditors to ensure consistency. - Early investment in low-carbon technologies

Leveraging the insights generated via granular carbon emissions measurement using AI-enabled tools like sentra.world, ferro alloy makers can put themselves in a pole position to chart out their decarbonization pathways. It is of paramount importance to marry internal data generation with industry benchmarks leveraging deep sectoral knowledge. By acting timely on the above 4 key steps, ferro alloy players have the opportunity to turn the looming threat of CBAM taxes and possible loss of market share into an opportunity to gain strategic market advantage.

How can Ferro-Manganese makers Decarbonise their operations?

Ferro-Manganese producers can rely on multiple technological interventions to reduce their carbon footprint while improving their operational efficiency.

- Submerged Arc Furnace (SAF) Optimization

- Furnace Automation and Control: Advanced control systems can optimize the operation of Submerged Arc Furnaces (SAF) used in ferro manganese production. These systems can precisely regulate temperature, current, and voltage, improving energy efficiency and reducing fuel consumption.

- Waste Heat Recovery: SAFs generate large amounts of heat, much of which can be captured through waste heat recovery systems. This heat can be reused for preheating raw materials, generating electricity, or other purposes, significantly reducing energy needs and carbon emissions.

- Pre-reduction of Manganese Ores

Pre-reducing manganese ore before it enters the main furnace reduces the overall energy required for the smelting process. This step is achieved by using rotary kilns or shaft furnaces, where the ores are partially reduced using less energy, cutting down on overall carbon emissions. - Use of Alternative Reductants

- Biomass as a Carbon Source: Replacing traditional coke or coal with biomass can lower direct CO2 emissions.

- Hydrogen as a Reductant: Hydrogen-based reduction is being explored as a cleaner alternative to carbon-based reductants. The use of hydrogen can drastically reduce CO2 emissions, as it only produces water as a byproduct during the reduction process. However, this technology is still in the early stages of ferro manganese production.

- Electrification and Renewable Energy Integration

- Electric Arc Furnace (EAF): Ferro manganese can be produced using Electric Arc Furnaces (EAF), which can be powered by renewable energy sources such as wind or solar. This helps reduce Scope 2 emissions compared to the fossil fuel-driven energy typically used for SAFs.

- Renewable Power Sources: Transitioning to solar, wind, or hydropower for plant operations can significantly cut carbon emissions from indirect energy use. Even partial integration of renewables into the energy supply can have a large impact on reducing emissions.

CBAM takeaways for Ferro-Manganese Producers

To summarize, the following are the important takeaways for ferro-manganese and other ferro-alloy producers to ensure they ace CBAM reporting.

- CBAM Default values are high: By engaging in certified carbon footprint measurement exercise, Ferro-Manganese producers are highly likely to arrive at intensity values much lower than CBAM default values resulting in significant embedded intensity reduction for their customers.

- Operations data is precious and must not be shared: By relying on excel based templates to calculate and communicate their carbon emissions, ferro alloy producers risk leaking sensitive operational & commercial data to their customers. It is critical to leverage GHG calculation software such as sentra.worldto ensure fast & accurate measurement along with maintaining confidentiality.

- Critical to start decarbonization early: Ferro alloy producers will need to start their decarbonization journey now in order to meet the customer & regulator needs in time. Baselining & verification of baseline typically requires 3-4 months based on which decarbonization strategies will be formulated. It takes another 3-9 months (depending on scale/complexity) for a typical decarbonization intervention to get commissioned and produce verifiable results.